This past weekend I had the privilege to help install a chuppah for a marriage ceremony for close family. This chuppah (or huppah) holds a great deal of sentimental value to me, as it is the same one I designed for my own wedding six years ago. The wood pieces have held up pretty well in the intervening years. The chance to set it up and taking it down has made me reflect on my own wedding.

The Wedding Chuppah

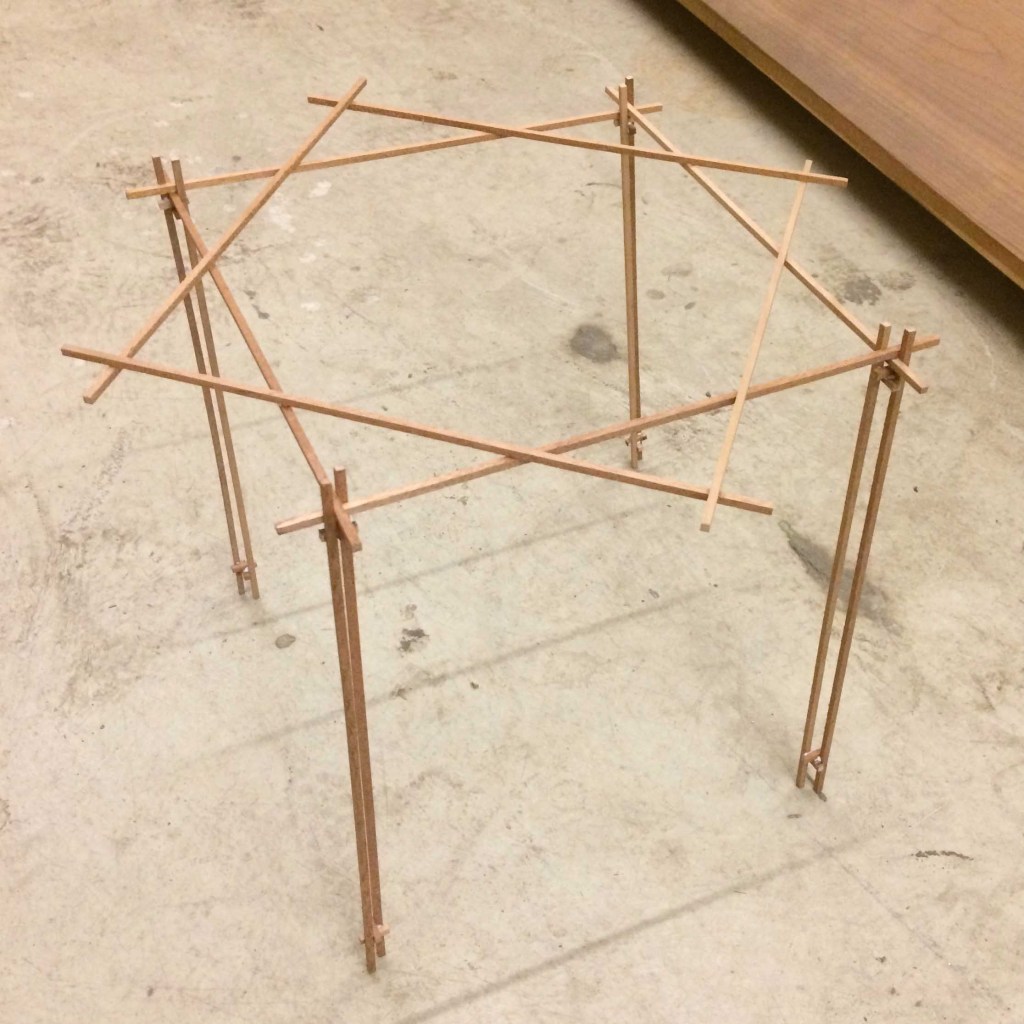

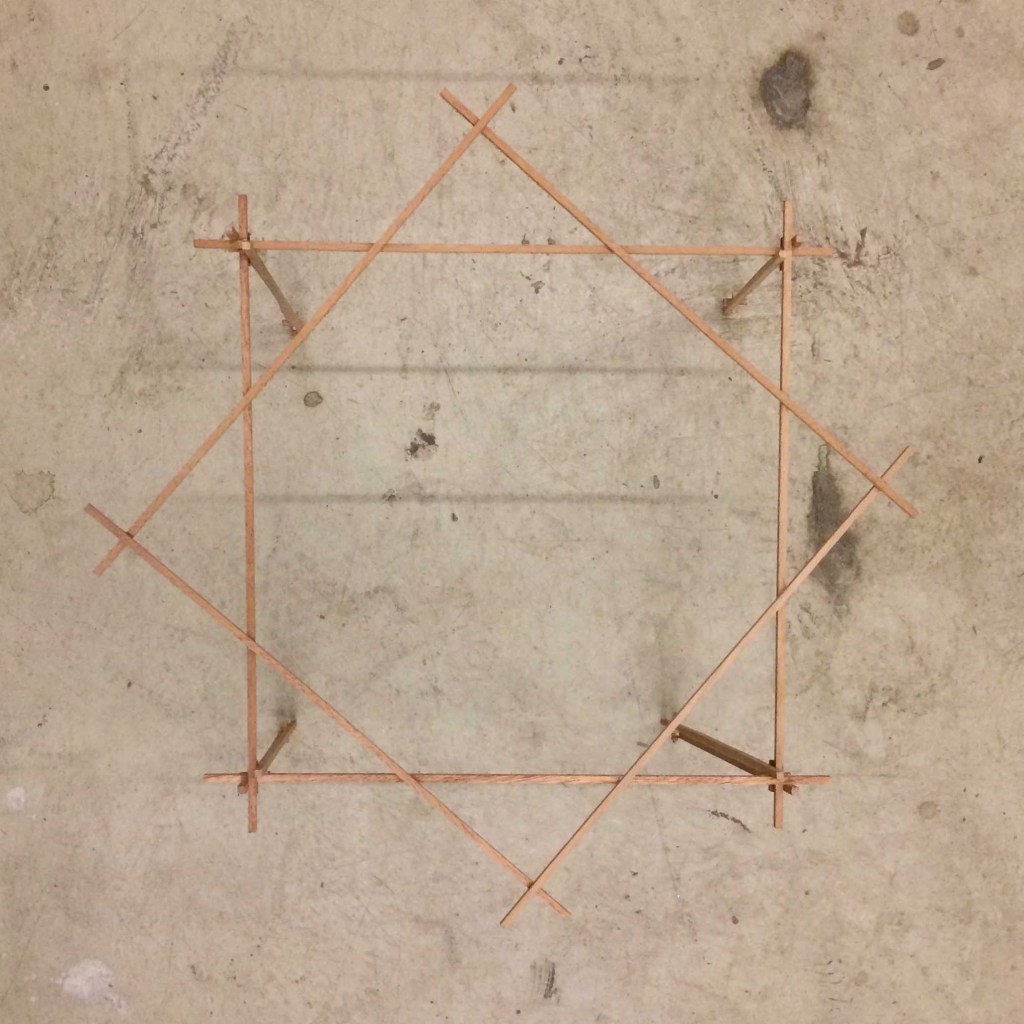

My wife and I met in design school and took the ceremony on as an opportunity to craft the experience and tell our own story. We wanted to pay tribute to our respective families, faiths and cultures. My wife is Jewish and we both wanted to include a chuppah, under which we would be wed. I wanted to pay tribute to my father’s Islamic and my mother’s Catholic faiths, and our chuppah evolved into an erstwhile ‘house of Abraham’, inclusive of all three faiths. From our wedding program: The Jewish bridal canopy symbolizes the home being established between Emily & Adam. This chuppah, like their home, pays homage to Islamic and Christian culture through the inclusion of the 8-sided star and cruciform joinery. Each post is held by a member of the wedding party.

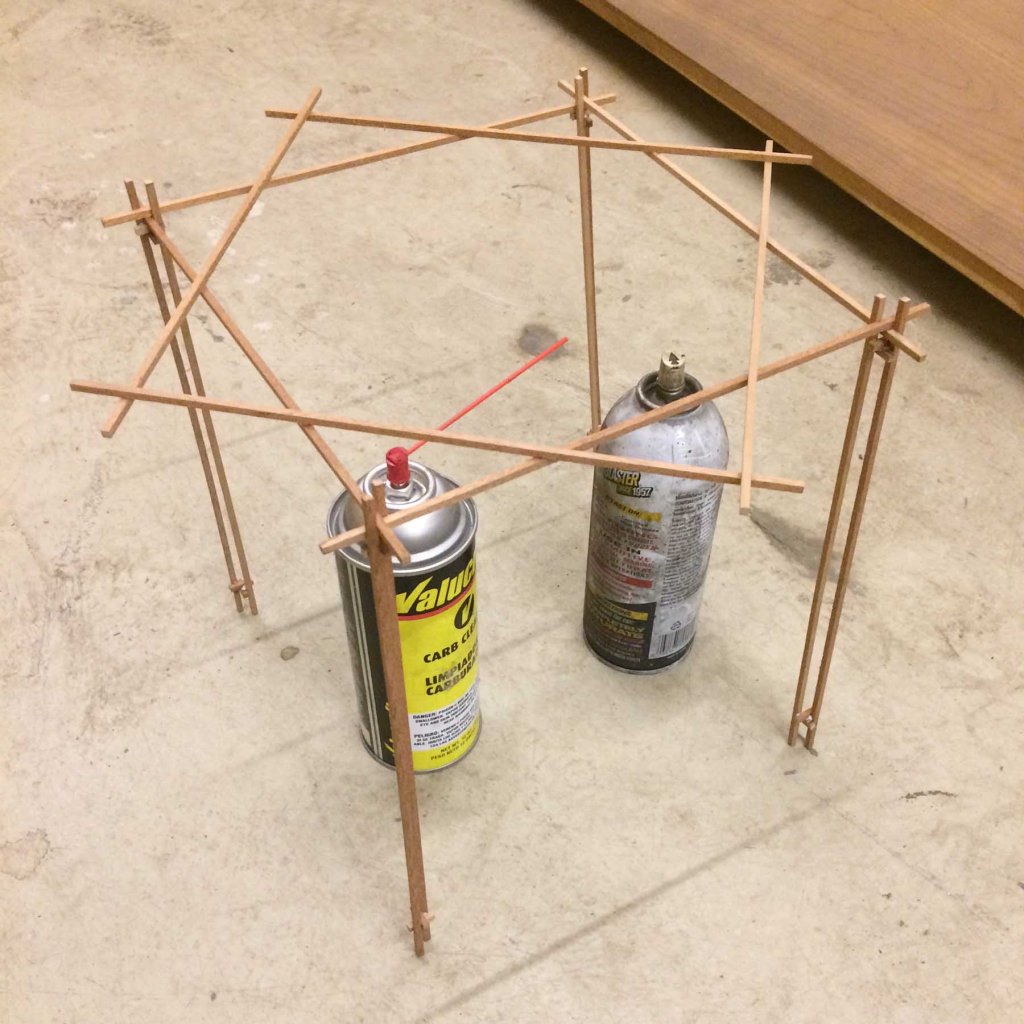

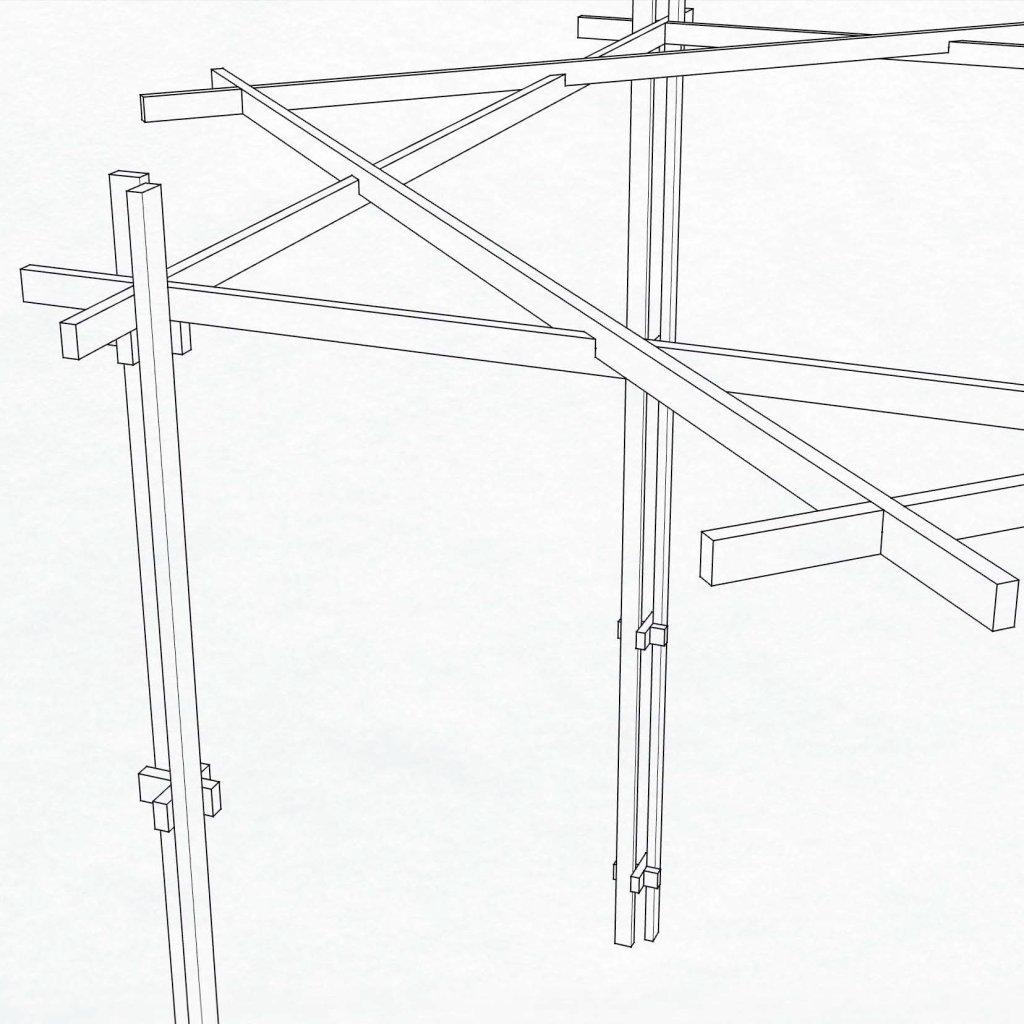

Chuppahs tend to include a wedding canopy supported at each corner by one of four posts, and they are intended to be temporary structures. I’ve read accounts describing the importance of making them light and requiring the help of other people to keep the chuppah upright, but often they are secured in place to make the wedding procession easier. Ours ended up staked to the ground in a tent-like fashion.

The design process was very straight forward and intuitive – I wanted to double the square frame of the canopy and double the wood at each post (mostly for stability). Initial plans (and scale model) used 1″x1″ molding/trim, but these seemed both flimsy and expensive. I went instead with 1″x2″ furring strips, making sure to sand, stain and seal each piece. The furring strips were susceptible to bowing and twisting – each post needed a few cross connections lashed together with plenty of twine to keep them straight. These connections, made from the same 1″x2″ lumber, allowed for the top frame to sit snugly between the two vertical pieces of each post.

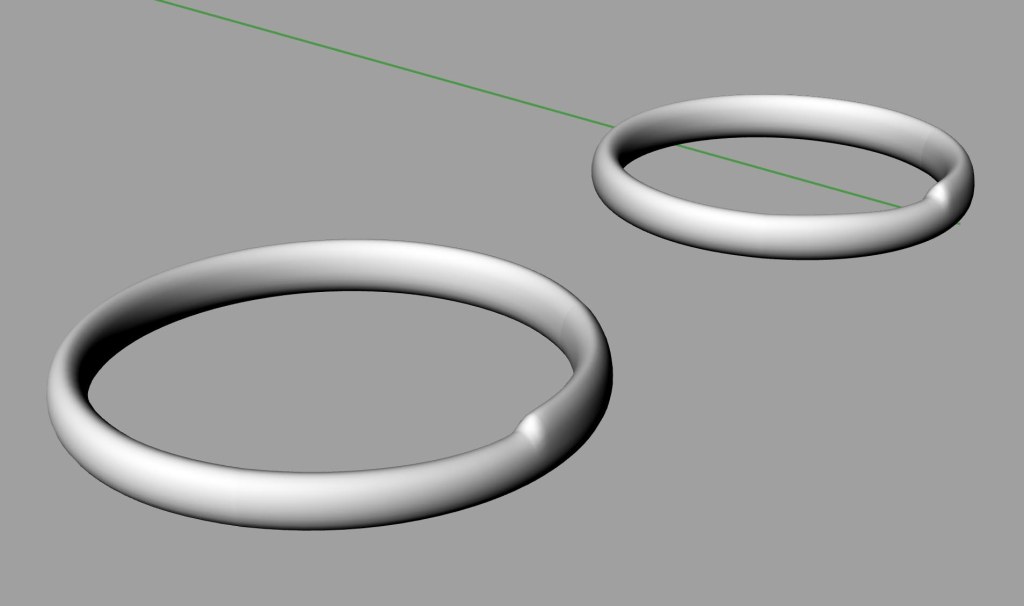

The Rings

The wedding also allowed us to explore what we wanted to make of our wedding rings. This was a rare case of ‘first thought – best thought’ as I sketched out a simple ‘notch’ in the band, then proceeded to sketch dozens of clumsier ideas. The custom jeweler – Carolyn M.A. Hearn – worked through a process of digital modeling, digital fabrication (3D printing), sanding and casting the rings. Sterling silver mock-up rings helped adjust and confirm the size and profile of the final 14K yellow gold wedding rings.

Each ring is identical in design, save for the ring diameters, and as complimentary geometry they fit together. I wear the silver ‘engagement’ ring on the inside, with gold wedding ring on the outside, and six years later never seem to tire of adjusting both bands to align the notch of each.

Very nice simple, meaningful wedding ring design ! You might consider having your design manufactured so that other married couples can wear and enjoy the meaning in your design.